|

|

|

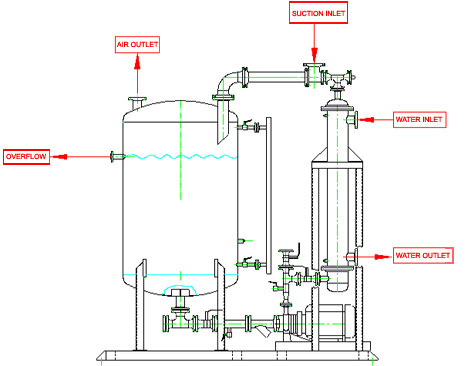

Scrubber SystemsThermoScrubTM

High Velocity liquids to remove

Contaminates From Gases

Operation

The gas and/or vapor stream to be treated is piped to the Suction Inlet. A pressurized liquid (typically water) is supplied to an expansion nozzle that will pass a high velocity liquid stream by the suction inlet. The suction fluids are attracted into the suction connection and aggressively mixed with the liquid. This high mixing efficiency promotes a transfer of entrained material from the gas into the liquid. Condensable vapors are condensed depending on the available temperature and pressure. Suction pressures can be a few inches of water draft pressure to a few inches of Hg Absolute. The mixture is compressed in the ejector diffuser section and discharged into a separator tank. Non condensables are vented at the top, liquid is separated out and stored in the tank to be treated as required for pH etc., pumped back to pressure, and cooled in the heat exchanger to begin the cycle again.

Advantages

- Complete Skid mounted packages of mechanical equipment provided for system safety and ease of installation.

- Large volume separator/storage tank for less frequent recharges

- Few moving parts

- Long life and low maintenance with corrosion resistant materials

Features

- ASME Code Section VIII, Div. 1 Stamped vessels, 100 Psig design pressures

- ANSI B31.3 piping, 150 Psig design pressure

- Class 1, Div. 1, Group C&D equipment

- All corrosion resistant construction (316L SS, graphite, or Hastelloy) available

- Magnetic level indicator with high and low level alarm switches

- Seal less mag drive pump

- Welded piping, 150# flanged connections, Gylon 3500 gaskets, SS fasteners

- Local pressure and temperature indicators throughout

|

|

4611 S. University Dr. BLDG 109, Davie, FL 33328

508-486-9800, www.thermosysinc.com

email: service@thermosysinc.com National cellular: 508-561-2100 (24x7)

|