Particle Board Press SystemsThermoSweepTM

Particle Board Press Efficiency Enhancement Systems Through Condensate Removal

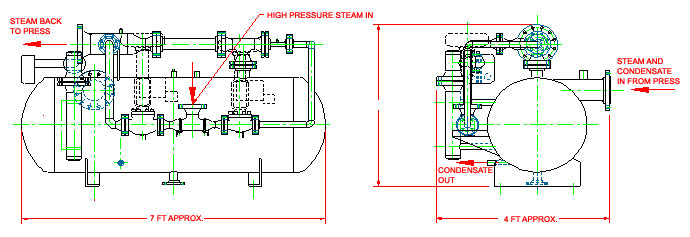

Operation

Steam and condensate from the press is delivered to the main tank inlet where it is separated. The condensate level in the tank is controlled with a float control and the condensate is discharged through a control valve. The steam is recycled through a steam jet compressor and delivered back to the press. Steam required through out the press cycle is modulated by control valves based on required press heating. Heat transfer through the press platens is improved with increased circulating-steam velocity and condensate is swept through preventing uneven heating (cold spots).

Benefits

- Rejects are reduced from a typical level of 10% to about 1%

- Cycle time is generally cut in half, overall production rates are increased 25-30%

Features

- ASME Code Stamped vessel

- ANSI piping

- Steel construction

- Fully packaged for easy installation

Click here to Contact Us About Press Systems!

|